Preparing your blog post

Preparing your blog post

Refcool partnered with Varian Medical to develop and service a hybrid chiller for linear accelerators (Linacs), combining traditional cooling and free cooling to provide reliable, energy-efficient cooling water for life-saving oncology equipment.

Varian Medical Systems, the leading supplier of linear accelerators used in cancer treatment, requires absolute confidence in the cooling systems that support their life-saving machines. Linear accelerators (Linacs) generate heat and rely on precise water cooling to operate safely and continuously. Varian turned to Refcool for both maintenance services across the UK and Ireland and for innovative cooling designs to enhance system reliability. In response, Refcool developed a “hybrid chiller” solution that ensures Linacs receive uninterrupted, efficient cooling. This hybrid design smartly combines a standard air-cooled chiller with an air-blast (free) cooler, optimizing cooling based on ambient conditions.

In a clinical environment, any downtime of a Linac is unacceptable – patients’ treatment schedules depend on the machine’s availability. Thus, the cooling system’s challenge was twofold: uncompromising reliability and energy efficiency. Specifically:

Reliability: The cooling unit must provide precisely controlled water temperature to the Linac, 24/7, with redundant features to prevent failures. Hospitals demand continuous operation without interruptions, so the cooling system needed failsafes or backup capacity. Moreover, Varian required a partner who could maintain these systems proactively across many sites, ensuring trouble-free service for hospitals.

Precise Control: The temperature of the cooling water has to be tightly regulated because even small fluctuations could affect the Linac’s performance or calibration. The challenge was to hold the temperature stable under varying loads (a Linac might heat more during intense use) and varying ambient conditions.

Energy Efficiency: Linacs run daily, and their cooling systems consume a lot of power. Varian and the hospitals would greatly benefit from any design that could reduce energy usage (and waste heat) while still ensuring cooling. Free cooling (using outside air when cool enough) was an attractive concept to integrate, but merging it with a mechanical chiller in a seamless way was a technical hurdle. The cooling system had to intelligently switch or combine modes (traditional refrigeration vs. using ambient air) without sacrificing the stable outlet temperature.

Space and Integration: These hybrid chillers would often need to fit into existing hospital infrastructure or new installations with limited space. The solution had to be compact and easy to integrate with Varian’s Linac systems and controls.

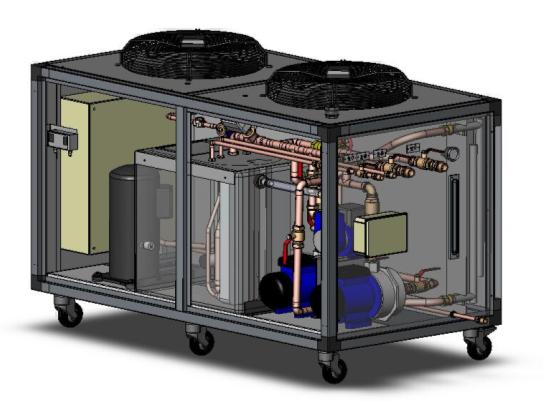

Refcool’s answer was the development of a Hybrid Chiller System for Varian’s linear accelerators. This system essentially marries two cooling technologies:

A traditional air-cooled refrigeration chiller – which can actively chill water using compressors, condensers, etc.

An air-blast free cooler – which can dissipate heat using just ambient air (when the outdoor temperature is low enough) without running compressors.

These two components were integrated into one packaged solution with a smart control algorithm. Under normal moderate conditions, the hybrid chiller runs in high-efficiency mode: using the refrigeration circuit to bring water to the required temperature, while the free cooler pre-cools the return water whenever ambient conditions allow (e.g., on a cool day or night). During cold ambient conditions, the system can switch to a mostly free cooling mode, where the air-blast cooler alone might maintain the temperature, barely needing the compressors – greatly reducing energy consumption. Conversely, on hot days or when the Linac is under heavy use, the mechanical chiller does the heavy lifting, with the free cooler perhaps assisting if it can.

The controls are key: the hybrid chiller’s controller constantly monitors ambient temperature and the Linac’s cooling water temperature, deciding the optimal mix of free cooling vs. mechanical cooling. This ensures the Linac always receives cooling water at the precise setpoint, while minimizing power draw.

Redundancy and reliability were also built in. The chiller portion had multiple compressors and robust components (plus backup power arrangements in some installations), and the dual cooling sources (refrigeration and free cooling) inherently provided a backup pathway. For example, if a compressor was to fault, the free cooler could still dissipate some heat, and vice versa. Refcool also established a flexible, bespoke maintenance contract to service these cooling systems for Varian. Our service teams schedule regular maintenance and are on call across the UK and Ireland to respond quickly, ensuring uptime is maximized for each site.

The hybrid chiller units were designed with hospital environments in mind: low noise operation, compact footprint, and compatibility with hospital facilities management systems. We included features like fully hinged access panels for easy servicing (important for Varian’s field engineers and our techs), quick-connect bypass loops for temporary backup chillers (if ever needed during maintenance), and high-quality components to meet medical device standards.

The implementation of the Hybrid Chiller solution has provided Varian and its hospital clients with a major reliability and efficiency boost. Key outcomes include:

Uninterrupted Operation: The linear accelerators are now cooled by a system that virtually guarantees continuous operation. The hybrid chiller’s redundancy and the support from Refcool’s maintenance team mean cooling failures are exceedingly rare. Hospitals have been able to schedule continuous patient treatment sessions with confidence, meeting their tight appointment slots without cooling-related delays. In effect, patient care is never compromised due to cooling issues – a huge win for all stakeholders.

Energy Savings: By optimizing cooling mode based on weather, the hybrid chiller significantly reduces energy consumption. In cooler months or climates, the free cooling mode handles a large portion of the load at a fraction of the energy cost of running compressors. Varian has noted that this design greatly reduces the hospital’s carbon footprint for the Linac installations. This greener operation is a strong selling point for Varian when they pitch their systems, aligning with many hospitals’ sustainability goals.

Precise Temperature Control: The water temperature to the Linac is kept rock solid at the required setpoint. The hybrid approach did not compromise performance; in fact, by smoothing out the load on the compressors, temperature fluctuations are minimized. Linac operators and service engineers have reported that the machines operate within optimal temperature ranges consistently, which also can enhance the life of the Linac components.

Varian’s Trust and Partnership: Refcool’s role as a service provider across the UK and Ireland has been solidified. Varian entrusted us with a nationwide contract to commission and service these cooling units, demonstrating their confidence in Refcool’s expertise. This ongoing relationship means Varian can focus on their core technology (the accelerators) while Refcool ensures the thermal management side is always under control.

Positive Patient Impact: While it’s indirect, the ultimate beneficiaries are patients. Treatments on Linacs are rarely interrupted or rescheduled due to technical issues, partly thanks to the robust cooling. Each hybrid chiller quietly ensures that the cancer treatment equipment runs flawlessly, which translates to patients getting their therapy on time and clinics maintaining throughput.

In summary, the Hybrid Chiller project with Varian exemplifies how Refcool delivered an innovative solution that meets the high-stakes demands of medical equipment cooling. It combined cutting-edge engineering with practical reliability measures and strong service support. For prospective B2B customers, especially those in medical or high-tech fields, this case study is a persuasive testament to Refcool’s ability to enhance equipment performance and dependability through smart cooling solutions.