Preparing your blog post

Preparing your blog post

Refcool partnered with a UK UV systems manufacturer to develop specialized air-blast and water-to-water cooling units for high-power ultraviolet lamps, enabling safe, efficient operation of UV curing and drying equipment sold worldwide.

Ultraviolet (UV) curing and drying systems are used in industries from graphic arts printing to medical device manufacturing. These systems utilize high-power UV lamps that generate intense light – and with it, intense heat. A UK manufacturer of UV drying equipment faced the challenge of keeping their lamp units cool to prevent overheating and fire hazards. For over 20 years, Refcool has been a key cooling partner for this manufacturer, supplying specialist water and air coolers that integrate into their UV systems. This case study highlights how Refcool’s cooling solutions have enabled the client to safely operate high-power UV lamps and achieve global success with thousands of units in the field.

UV lamps used for industrial curing can have very high power inputs. If not properly cooled, the lamp assemblies can reach extreme temperatures, posing risks of lamp damage or even fire, especially in continuous operation. The client needed a cooling solution that could be packaged with their UV drying systems to ensure each lamp stays within safe temperature limits. The challenges included:

Dual Cooling Mediums: Some UV systems benefit from air cooling, blowing cooled air across the lamps, while others use water cooling (circulating chilled water around the lamp housing) depending on the application. The manufacturer wanted to offer both types (air-blast coolers and water-to-water coolers) for different product lines.

Compact Integration: The coolers had to be fully packaged and easily integrated into the client’s UV units. That means relatively small form factors, simple connections, and reliable operation with minimal maintenance – since these UV units are often sold as turnkey machines to end-users.

Efficiency and Reliability: UV systems often run continuously in production environments. The cooling units needed to be highly reliable to allow 24/7 operation and also energy-efficient so as not to add exorbitant running costs to the UV system. Additionally, since many UV systems are used in clean or controlled environments, the cooling units had to operate without introducing contaminants or excessive noise.

Global Deployment: The manufacturer sells thousands of these UV drying systems worldwide. Thus, the cooling solutions needed to be robust across different climates and have globally available service (Refcool’s long-term support arrangement would be key here). Competitive pricing was also a factor, to keep the overall UV system cost attractive in the market.

Working closely with the client’s engineering team, Refcool developed a range of fully packaged cooling systems tailored for UV lamp applications. The two main categories of products delivered were:

Air-Blast Water Coolers: These are essentially chiller units that provide chilled water to the UV lamp housing. The lamp assemblies have channels or coils where water circulates, absorbing heat directly from the lamp housing. The heat is then carried to an external Air-Blast cooler supplied by Refcool. This unit combines a refrigeration circuit (or fan-coil system) and blows air over a radiator to dissipate the heat from the water. It’s “air-blast” because it uses air to remove heat from water (as opposed to using a cooling tower or similar). These units were designed to keep water at a precise temperature that optimizes lamp performance and life.

Water-to-Water Cooling Systems: In some facilities, chilled water might already be available, or a separate chiller is preferred. For those, Refcool provided a water-to-water heat exchanger system. This system takes the facility’s chilled water and passes it through a heat exchanger to cool a secondary clean water circuit that goes through the UV lamp. The separation ensures that if the facility water is not pure, it won’t contaminate the lamp cooling circuit. It also isolates vibrations and pressure differences. Refcool packaged these with all necessary pumps, controls, and valves to make them easy to install with the UV units.

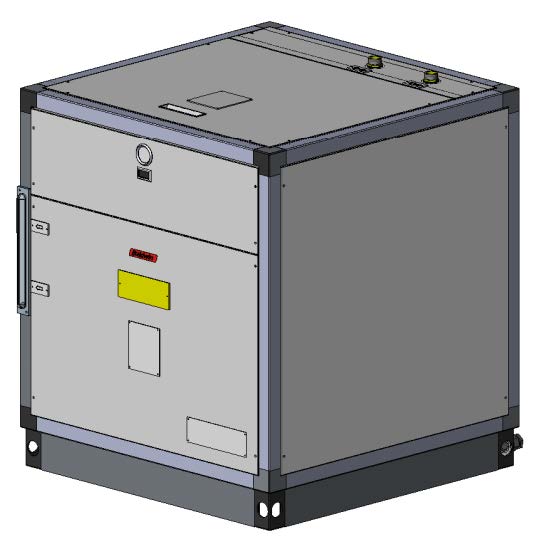

Both types of systems were fully self-contained and packaged for easy integration. They featured temperature controls to maintain the UV lamp cooling water/air in the correct range. Safety interlocks were included so that if cooling flow or temperature was out of range, it could signal the UV system to shut down lamps to prevent damage. Physically, the units were built to fit into the footprint or enclosure of the UV drying equipment where possible, or as a small auxiliary box that accompanies the main machine.

One of the keys to success was the long-term partnership and iteration. Over 20 years, Refcool and the client fine-tuned these designs. Improvements were continually made in energy efficiency (such as using more efficient compressors or fans in newer generations), noise reduction (important for operator comfort), and ease of maintenance (filters that can be changed easily, standardizing parts for global availability). Refcool’s ability to maintain a competitive price structure was helped by this long relationship and the volume of units – the client could count on favorable pricing, making their overall product more competitive.

The collaboration between Refcool and the UV system manufacturer has been a resounding success, evidenced by the deployment of thousands of UV drying systems worldwide that utilize Refcool’s cooling technology. The end users of these UV systems (printing companies, manufacturing plants, etc.) benefit from equipment that operates safely and reliably. The UV lamps are kept within safe temperatures, eliminating the fire hazard and drastically improving lamp life and consistency of curing performance.

Thanks to effective cooling:

The UV curing processes can run at higher power and speeds, since overheating is no longer the limiting factor. This increased productivity for the end users is a direct selling point of the manufacturer’s equipment.

There have been minimal field issues related to cooling. The robust design of the air-blast and water-to-water coolers has meant they run continuously with only routine maintenance. The manufacturer is confident offering lengthy warranties on their systems, knowing the cooling component – often a critical part – is well handled.

The partnership’s longevity (20 years and counting) has ensured a competitive price and service structure. The client can price their UV systems favorably and also assure customers of good after-sales service (with Refcool’s support). If a service need arises in the cooling unit, Refcool is there to assist, directly reflecting well on the manufacturer.

Environmentally, the new generations of these cooling units have improved efficiency and often use refrigerants with lower global warming potential (where refrigeration is used), aligning with modern sustainability goals. Additionally, because the lamps run cooler, there’s less wasted energy as excess heat – more of the input power goes into useful UV light rather than being lost as heat.

This case stands as a persuasive example of co-engineering success. By developing customized cooling solutions for a specific industry need (UV lamp cooling), Refcool enabled the client to deliver a superior product. It highlights Refcool’s strengths in innovation, long-term collaboration, and the ability to adapt standard cooling technologies (like chillers and heat exchangers) into special-purpose solutions. For any business dealing with high-heat devices or looking to integrate cooling into their equipment, the UV lamps cooling partnership showcases how Refcool can add value, ensuring safety and performance go hand in hand.